Common Questions

Frequently Asked Questions

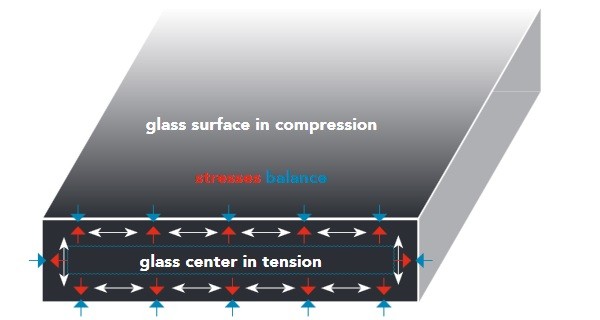

Tempered glass belongs to safety glass.It’s produced with tempering glass furnace.The glass will be heated into 670 -720 degrees in the tempering furnace first and cooling down the glass quickly with cool wind.The heating &cooling process temperature and time used for different thickness glass are different,but the aim is to form a compressive stress on glass surface.

When the glass is subject to external force,the surface stress is been counteract first to improve the bearing capability and enhance the glass strength.

Tempered glass has high strength and will break into small particles once broken and avoid potential injury to people.

The appearance of float glass and tempered glass are same,you cannot see clearly whether the glass been tempered or not,here are 2 methods that helps you:

- Check the glass logo. Tempered glass will has tempered logo on glass surface,the logo are usually 15*15mm and can be found on glass corners,with printed glass standards or related words,such as CSI,SGCC,EN12150,CCC,Kitemark etc.The logo cannot be removed with alcohol,and even knives,it combined with glass firmly.

- 2.Check the glass flatness.Before tempering process,float glass is absolutely flat,after tempering process,glass will have slightly overall bow or local bow,if you put hand on glass surface,you’ll feel that the surface is not smooth,or please check the glass vertically and see if any bending at glass center.Now glass tempering process is becoming very advanced and glass flatness is hard to be noted now.

The middle part of the tempered glass is the strongest, and the four corners and edges are the weakest. Once the edges or corners are hit, the whole piece of glass is easily broken.

Because the existing of Nis in tempered glass ,there’s always spontaneous breakage after glass installation,which brings high maintenance and replacement costs.Heat soaking test is good solution to test the toughened glass and reduce the probability of self-explosion and ensure quality,the shattering proof process is used for high requirement projects.Learn more about glass spontaneous breakage.

Tempered glass price is quite different,it’s decided by the glass types,glass thickness,glass sizes,glass quantity used and the distance between your house & glass factory.The raw materials in different countries varies too,here we just take China as example,below is reference price:

5mm tempered glass:USD10/SQM, 10mm clear tempered glass: USD20/SQM.

Low iron tempered glass and body tinted tempered glass is about 15-20% higher than clear tempered glass.

Other extra process,drilling holes,notches,cut-outs,round corners will have extra costs.

This is the typical price in China,in developed countries,the price maybe 3-4 times higher for higher labor costs.

If you got large scale tempered glass requirement,China glass factories is good option to save costs.

The tempered glass strength is 3-5 times higher than normal float glass,and international glass standards,BS EN12150,ASTM C1048,AS/NZS2208 have similar impact test requirement against tempered glass to test the glass strength and evaluate the tempered glass safety.

The impactor is a ball filled with metal grains,or dual tires weight about 45 kgs,and fall from different heights,usually 350mm,750mm and 1200mm to see if the glass break or not,this is to simulate people hit on glass.Below video shows the different result of tempered glass and float glass.

When the impact force is bigger than glass strength,the tempered glass will shatter into small particles,it won’t hurt people.

Beside that,tempered glass has good thermal stability, can withstand a temperature difference of 3 times that of float glass, and can withstand a temperature difference of 200°C.

After glass tempering process,Uniform compressive stress is formed on the surface and tensile stress is formed inside,the compressive stress is quite balance. The tempered glass cannot be cut ,grinding or drilling holes any more, otherwise it will be broken due to the destruction of the uniform compressive stress balance.

So before you decide to install the tempered glass,make sure the sizes are measured correctly and precisely ,once glass process is finished,it cannot be changed any more.

Cleaning the tempered glass is quite easy,usually clean water and lint free towel or cloth is enough to remove most dirty and dots on glass surface.While for some frequently used glass,especially shower door glass,after years water & chemical corrosion,glass becomes hard to clean,please check our another article: 9 methods to clean Glass shower door-Maintenance Guide

Cleaning your normal tempered glass,please refer to our post:Building Glass Maintenance guide

If any glass broken in your home,keep calm.

The fragments of tempered glass is very small,what you should do first ,is to break it and collect all the fragments caused to avoid future potential injury.

The glass replacement for your broken tempered glass is quite easy,please contact the local glass replacing companies,they will help measuring the glass size and replace it within just several days.

Sometimes the replaced glass is not tempered glass,or it’s just float glass,you can stick films on glass to hold the whole glass.The film can not only have some extra functions,such as offering privacy,decoration ,but most important is,once the glass broken again,the film can hold the glass can prevent glass injury.